GrainSentinel Real-Time Grain Storage Monitoring & Control

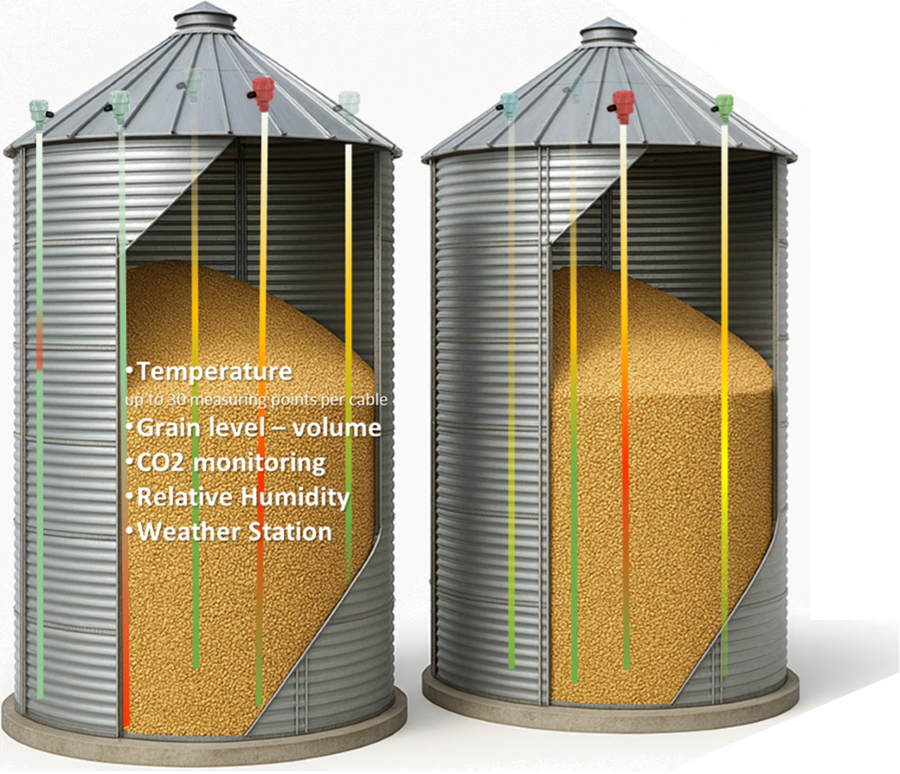

24/7 temperature, CO₂, humidity, and moisture monitoring — directly inside your silos.

AgriTech 4.0

What is GrainSentinel?

GrainSentinel is an advanced solution designed by EGIDION to provide real-time monitoring and control of grain storage conditions.

By integrating temperature, CO₂, relative humidity (RH), and volume measurements, GrainSentinel ensures optimal storage conditions, reduces spoilage, and enhances operational efficiency.

Why Chose GrainSentinel?

Storing grain isn’t just logistics — it’s risk management. Heat pockets, moisture migration, CO₂ buildup, and pest activity silently eat into your margins. Traditional monitoring systems detect problems too late — when damage is already done.

GrainSentinel changes the game. It’s a fully integrated monitoring system that gives you real-time data, automated alarms, and local decision-mlking — right where you need it.

- Early Warnings: Detect heating, condensation, and infestation before spoilage begins

- Less Spoilage: Reduce grain losses and improve operational efficiency

- Safer Fumigation: Trigger PH₃ only when needed — and monitor it in real time

- Reduced Energy Use: Automate aeration based on actual conditions, not guesswork

- Full Traceability: Meet compliance and export requirements with complete audit trails

Everything is included to monitor your grain

- In-silo sensor cables: Up to 30 temperature points per cable, ATEX certified

- Grain level measurement: Accurate volume tracking

- CO₂ + RH% probes: Roof-mounted detection for biological activity

- Prewired rooftop boxes: Power + comms via PoE or 24VDC

- Weather stations: Optimize airflow and drying

- SiloIQ Controller: Local dashboards, alarms & logic (no cloud needed)

AgriTech 4.0

SiloIQ: Your Grain Brain

SiloIQ is EGIDION’s industrial edge controller that locally manages all sensor data, automation logic, and real-time dashboards for your silos — fully offline, secure, and cloud-free

No cloud needed, zero vendor lock-in

- Supports 10,000+ sensors

- SCADA-ready

- Fan/actuator logic with full offline resilience

- Remote support via secure VPN

Compliance-first design: operates even in data-restricted countries.

Smart.

Scalable.

Field Ready.

GrainSentinel is designed for real-world operations where time, reliability, and traceability matter.

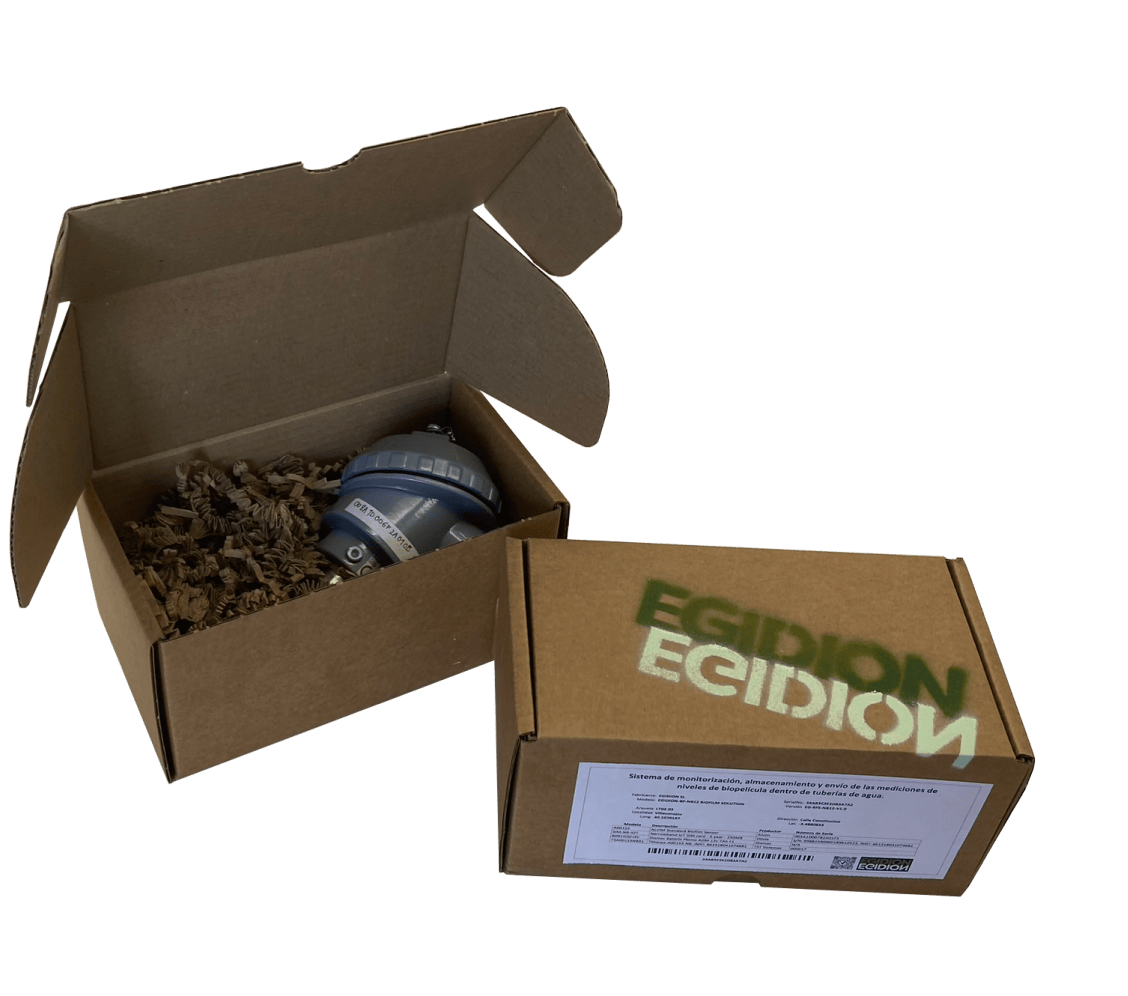

From day one, you get a complete, field-tested system with all components preconfigured — no black boxes, no surprises.

- Fast Deployment: From order to operational in just 4–6 weeks

- Factory-Tested Kits: Pre-labeled, bench-tested components with clear wiring diagrams

- On-Site Support: 2 weeks of field support included for installation and training

- Fixed Pricing: Transparent scope with no hidden costs

- ATEX Certified: Sensors built for explosive dust environments

- Traceability by Design: Full data logging, audit trails, and compliance-ready reporting

- Open Protocols: Integrates via Modbus RTU/TCP, OPC-UA, and MQTT — no vendor lock-in

- Works at Any Scale: From 2 silos to 200+, across sites and countries

- No Black Box: You own the system, the data, and the logic

- Backed by Experts: Designed and supported by a team with 20+ years in grain storage monitoring

Who it's for?

GrainSentinel is trusted by operators across the entire grain supply

chain — from storage to compliance.

Whether you're protecting national reserves or managing commercial stocks,

the system adapts to your environment, integrates with your infrastructure, and delivers the data you need to stay in control:

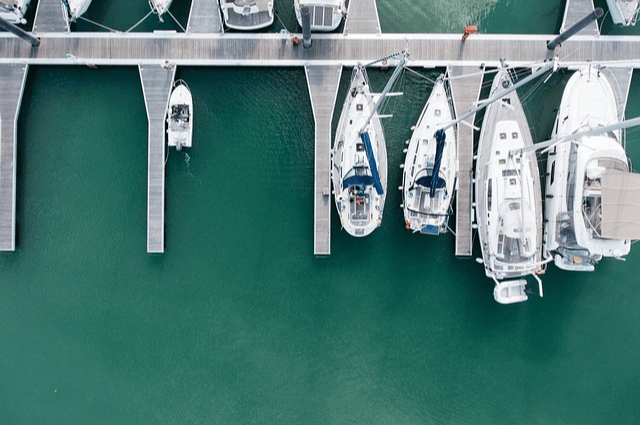

- Port-based Grain Silos: Detect heating, condensation, and infestation before spoilage begins

- Feed Mills, Cooperatives & Farm Silos: Reduce spoilage and ensure quality during storage and processing

- Government Food Reserves: Protect strategic stockpiles with full compliance and audit trails

- Commodity Traders & Importers: Ensure safe storage and minimize quality claims across sites

- Logistics Hubs & Storage Managers: Centralize control across distributed silos and warehouses

- Silo Builders & Integrators: Embed monitoring systems as part of turnkey storage solutions

- Insurance Providers: Demand reliable monitoring to reduce liability and verify loss claims

Our Industry Solutions

From idea validation and designing the customer journey to solution testing and piloting, and managing the successful scaling, we provide a comprehensive portfolio of IoT service design tailored specifically for grain monitoring systems. Our team of experts employs design thinking and value proposition design methodologies to ensure that every aspect of the solution is aligned with the customers' needs and expectations.